FIRST CLASS EFFICIENCY AND RELIABILITY

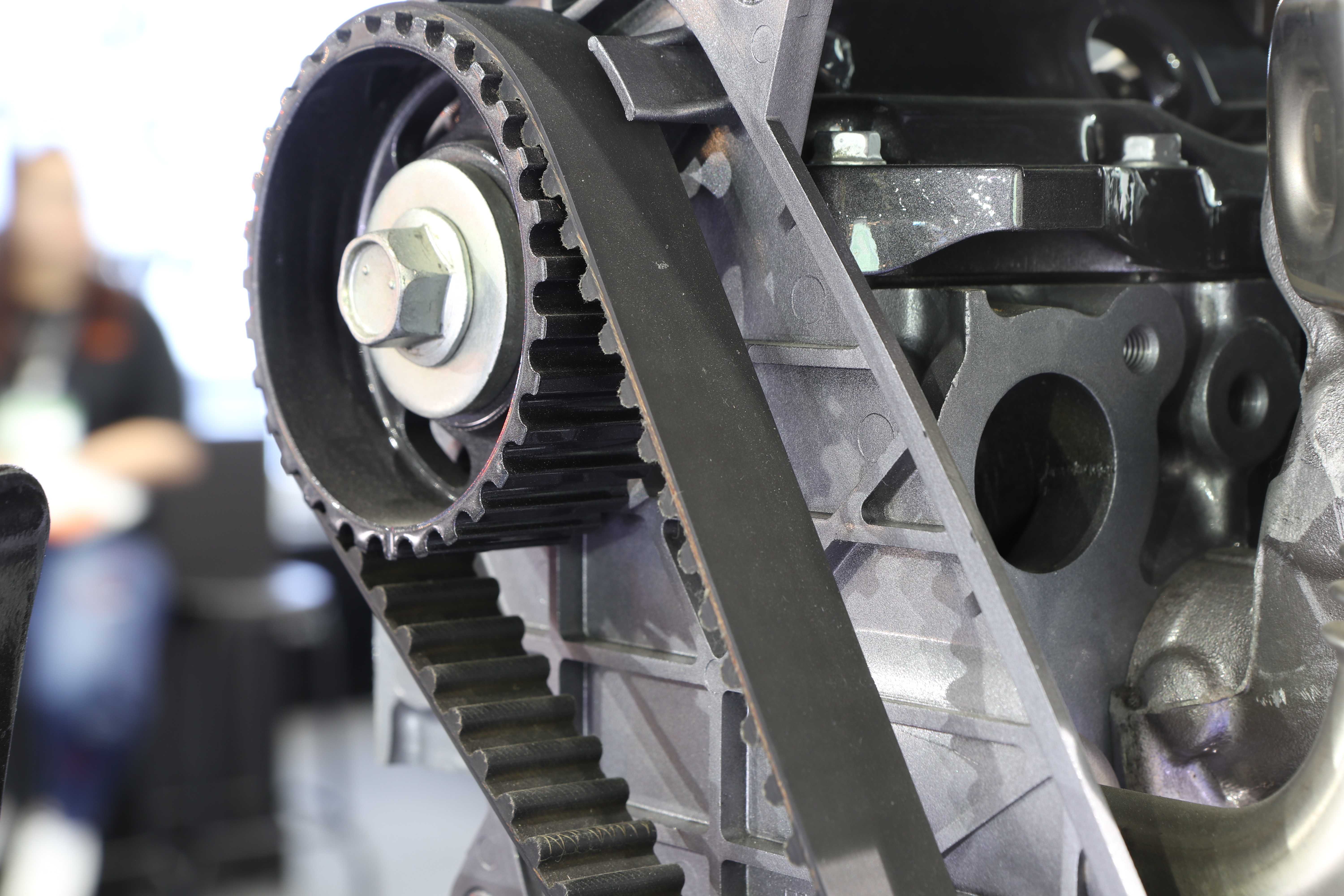

The OP timing belt is essential to guarantee perfect synchronisation between the moving parts of the engine and ensuring the correct system operation.

TIMING CHAIN KIT COMPONENTS

The components of the OP timing kits ensure that the crankshaft and camshaft movements are perfectly synchronised so that the intake and exhaust valves open and close at the right time according to the position of the pistons.

TIMING BELT

Each belt consists of 4 plies of reinforced HNBR rubber, designed using an advanced rubber compound and highly resistant, alternating-twist fibreglass cords. Furthermore, the teeth of the OP belt undergo the unique RFL (Resorcinol Formaldehyde, Latex) treatment providing a surface with:

- A protective heat shield

- Reduced abrasion

- Increased smoothness.

EXTREME ENDURANCE TEST

All OP belts undergo the most stringent OE tests, which simulate the temperature of the engine under stress at 130°C, for an uninterrupted life of 300 hours at a speed of 6000 rpm, with a constant pressure on the belt of 15 kg.

WITH DAYCO BELT

The Timing Kit with OP components is also available in a version with a DAYCO belt and a version with a DAYCO belt and water pump.

TYPES

STANDARD in chloroprene rubber

REINFORCED polychloropene or HSN (Hydrogenated Styrene-Diene) resistant to high temperatures up to 130°C.

REINFORCED - PLUS made of HNBR (Hydrogenated Nitrile Butadiene Rubber) with a high degree of hydrogenation that allows perfect mechanical adhesion between components, high tensile strength, non-stretching, absorption of pulsating loads and high-temperature resistance.

REINFORCED+TEFLON made of HNBR and a special PTFE (Teflon) film that is highly resistant to abrasion and ageing. Designed to minimise fabric wear in the latest generation of engines.

Other products in the range: