IDRAULIC PRECISION FOR SAFE AND CONSISTENT BRAKING

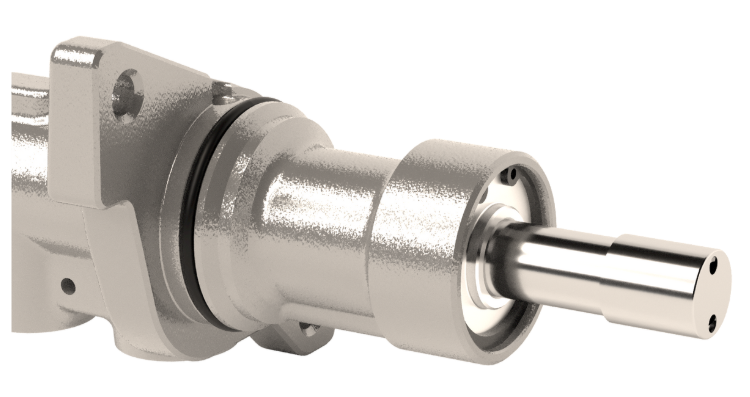

The brake's hydraulic system serves to convert pedal movement into pressure, transmitting it through the brake fluid to the calipers or brake shoes. The master cylinder and wheel cylinders are key components in ensuring that this force is transferred precisely and effectively, providing a prompt and controlled response from the braking system.

MATERIALS AND PROCESSING

Made of cast iron with galvanic treatment and anodized aluminum to enhance durability and resistance over time. The aluminum components are further finished with electrochemical deburring to eliminate micro-imperfections and protect the functionality and longevity of the rubber seals. Precision machining ensures effective sealing to prevent pressure loss that could compromise the efficiency of the braking system.

BRAKE CYLINDER

The rubber seal of the cylinder, responsible for maintaining hydraulic pressure, offers high resistance to tearing, wear, and the high temperatures reached by the brake fluid (around 150°C).

BRAKE MASTER CYLINDER

As a component subject to significant mechanical stress, the brake master cylinder undergoes multiple test cycles to assess the product’s strength and durability.

Other products in the range: