The range of spare parts brakes for Open Parts cars was designed to offer the highest performance and the highest quality, satisfying the needs of professionals in the sector. The components of the OP braking system are made with high quality components, respecting the same high quality and performance standards as the original OES spare parts.

Our wide range of products which includes brake pads, brake shoes, brake discs, brake drums, hydraulic components and brake fluids, is constantly updated, covering around 90% of the European car fleet, including all vehicle generations. Among the most popular applications are Peugeot 208, Volkswagen Golf, Dacia Sandero, Renault Clio, Toyota Yaris, Fiat 500, Citroen C3, Hyundai Tucson, Toyota Corolla, Mercedes A-Class, BMW Series and others.

4 BRAKING TECHNOLOGIES FOR EVERY VEHICLE

OP brake pads are designed with specific compounds tailored to the different categories of vehicles they are installed on, ensuring optimal performance and road safety.

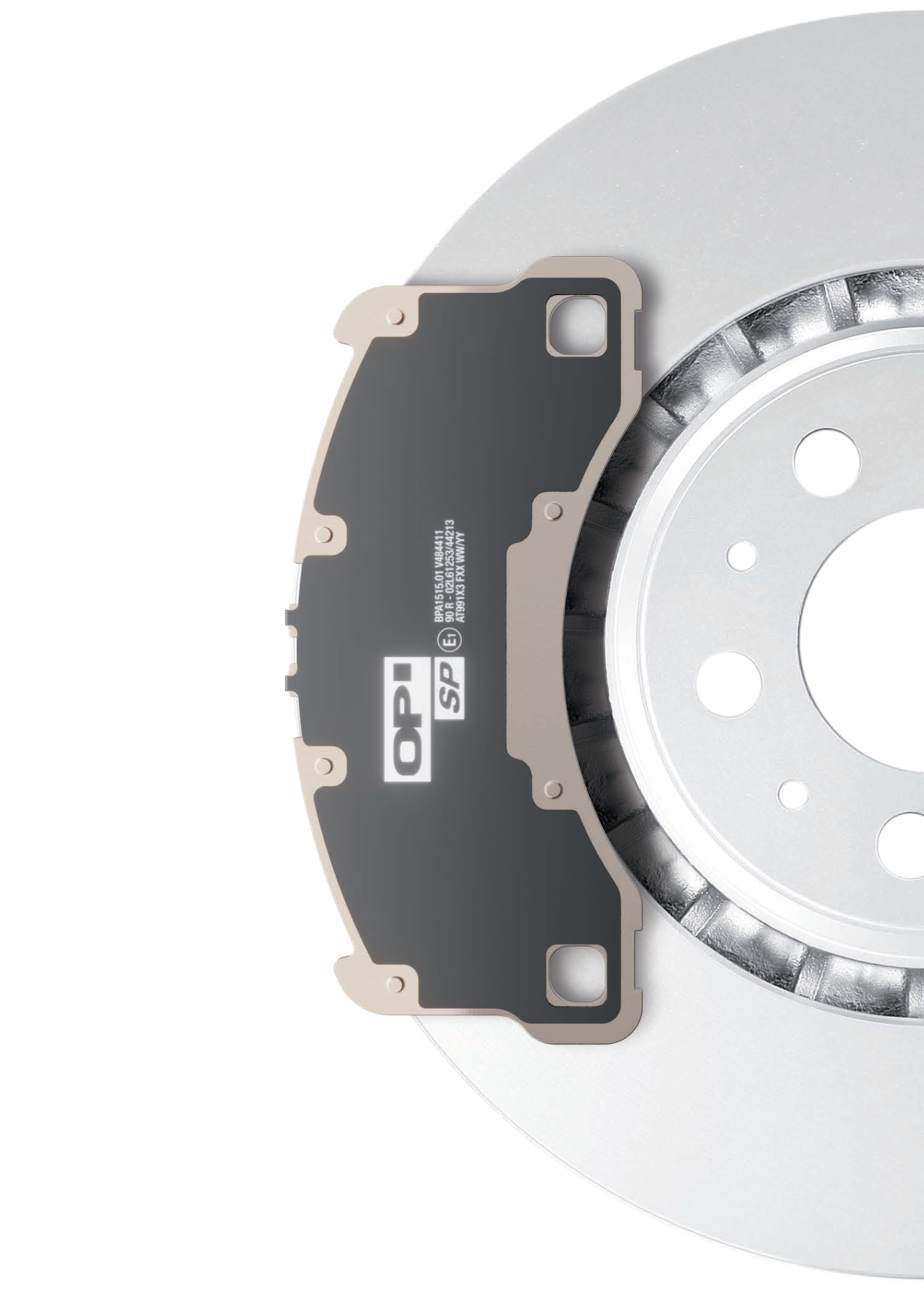

4 BRAKE DISC TECHNOLOGIES FOR HIGH PERFORMANCE ON EVERY TYPE OF VEHICLE

OP brake discs are made from GG20 grey cast iron with lamellar graphite and high-carbon GG15HC cast iron, ensuring excellent heat dissipation, wear resistance, and deformation resistance.

A COMPLETE KIT FOR TOTAL SAFETY

OP brake shoes, also available in kits, are made with rigid perforated friction material (HFM), ensuring progressive braking and preventing drum system lock-up.

SUPERIOR RESISTANCE

OP brake drums are designed for longevity and easy installation. Made from G26 pearlitic cast iron, they provide superior resistance even under heavy loads.

OMOLOGAZIONE ECE R-90

OP brake components comply with the safety and quality standards set by the international ECE R90 regulation—the only recognized standard capable of ensuring performance equivalent to the original. This regulation defines the design, construction, and performance requirements that friction materials for brake components must meet. We specialize in high-quality automotive components, and our range of braking system products has been carefully selected to meet the needs of workshop owners and auto parts dealers. We are always ready to provide assistance and support to help you find the right component for your vehicle. Become a distributor and discover the exclusive benefits we offer! Rely on us to ensure you provide your customers with the best braking components on the market.

BENCH AND ROAD TESTING

The efficiency and high performance of OP brake components are ensured through thorough quality control carried out at every stage of the production process. Dynamometer bench tests and road tests are essential to verify braking effectiveness and product durability. These tests also ensure compliance with ECE R-90 homologation standards.