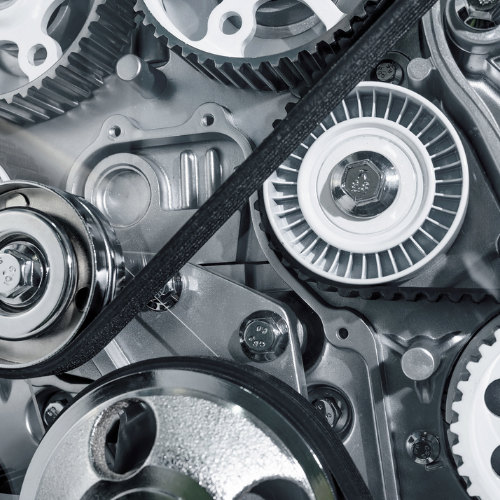

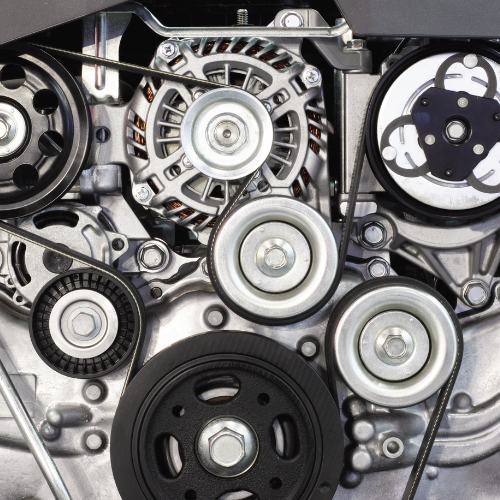

Designed for safe and efficient engine operation

News

TRIPLE SHIELD FOR TOTAL PROTECTION

OP antiallergenic and antimicrobial cabin air filters, with triple protection...

13 May 2025

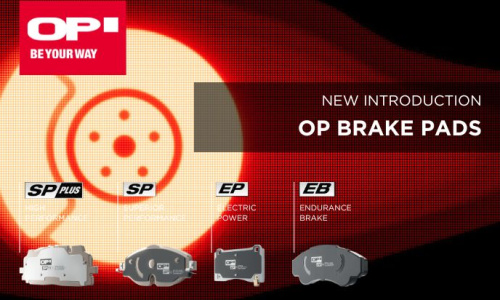

4 TYPES OF BRAKING FOR EVERY VEHICLE

The range now includes solutions designed to respond even more...

13 May 2025

A NEW ERA OF ELECTRONIC CONTROL FOR EVERY TYPE OF …

The OP sensor range is designed to meet the growing...

13 May 2025

NEW INTRODUCTION - AIR SUSPENSION COMPRESSORS

Air suspension compressors are now part of the Suspension family...

01 May 2025

SMOOTH AND EFFICIENT BOOT OPENING

With the goal of expanding our range of solutions for...

01 May 2025

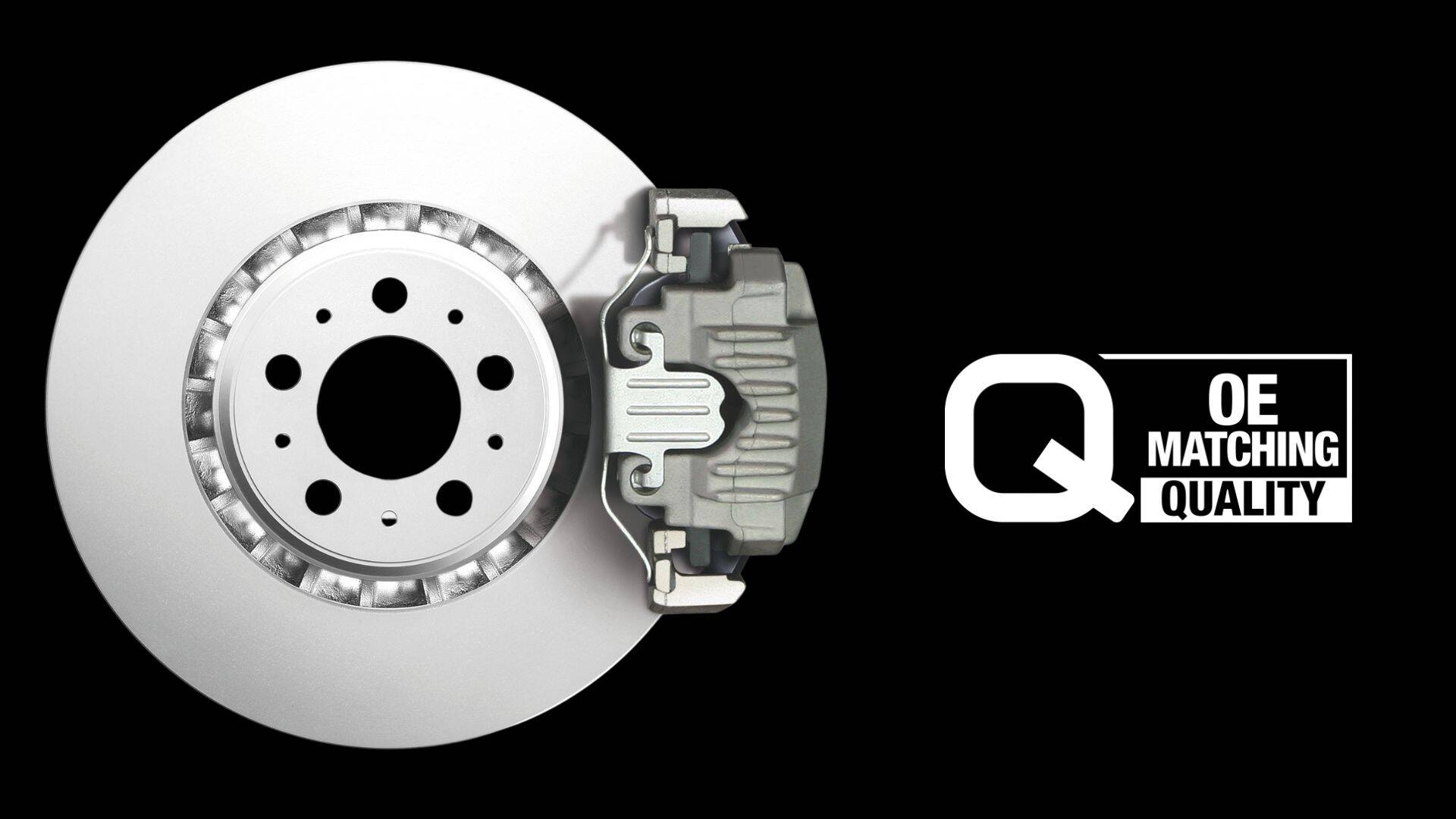

We don't compromise when it comes to

QUALITY

Behind every OP product there is the guarantee of quality certified by the IATF 16949:2016 standard, which certifies compliance with the technical specifications and production standards provided by the manufacturer and complies with EU Directive n°461/2010, which defines the parameters of spare parts of equivalent quality to the original.

CERTIFIED PRODUCTION

The quality of OP products is the result of a combination of several key factors. Production is certified and referenced from original equipment. State-of-the-art manufacturing facilities and innovative technologies result in finished, fault-free products with high quality standards and OE-compliant performance.

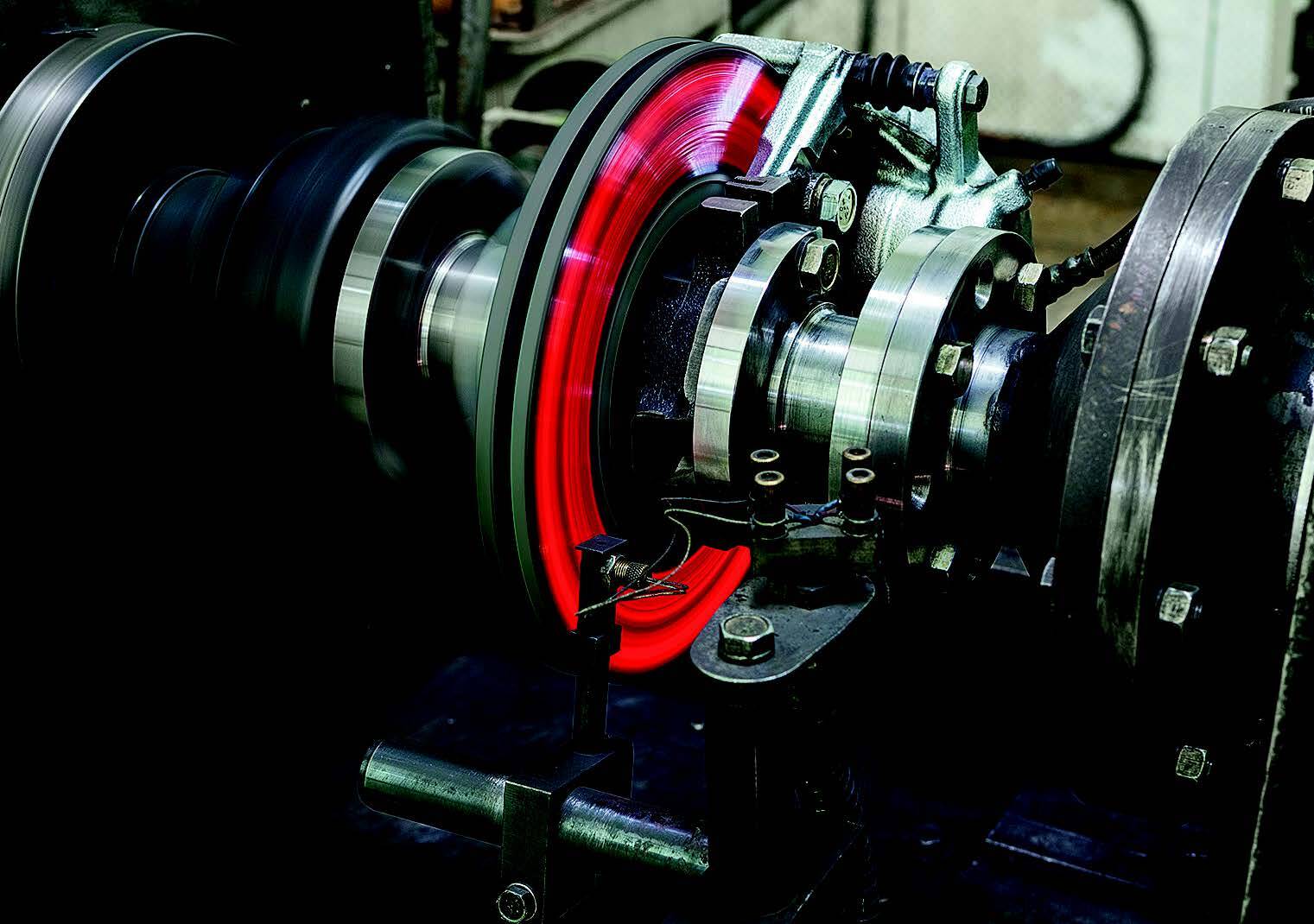

TOTAL CONTROL

OP spare parts are precisely tested to ensure high levels of safety and quality. In production, quality tests are carried out with respect to manufacturing and assembly tolerances on 100% of the production line; furthermore, additional qualitative resistance and durability tests are carried out on the finished product both on the test bench and on the road. Upon arrival to the OP central warehouse: random checks are carried out on incoming products at the innovative metrological laboratory. These further measurements are essential in order to further ensure an optimal final product ready for distribution.